Boosting overall plant health to increase yield

Zayndu's Z10 seed treatment system is the world's first 'activated air' seed processing system and has been shown to boost the consistency and rate of germination across a wide variety of crops including Microgreens, Herbs and Brassicas.

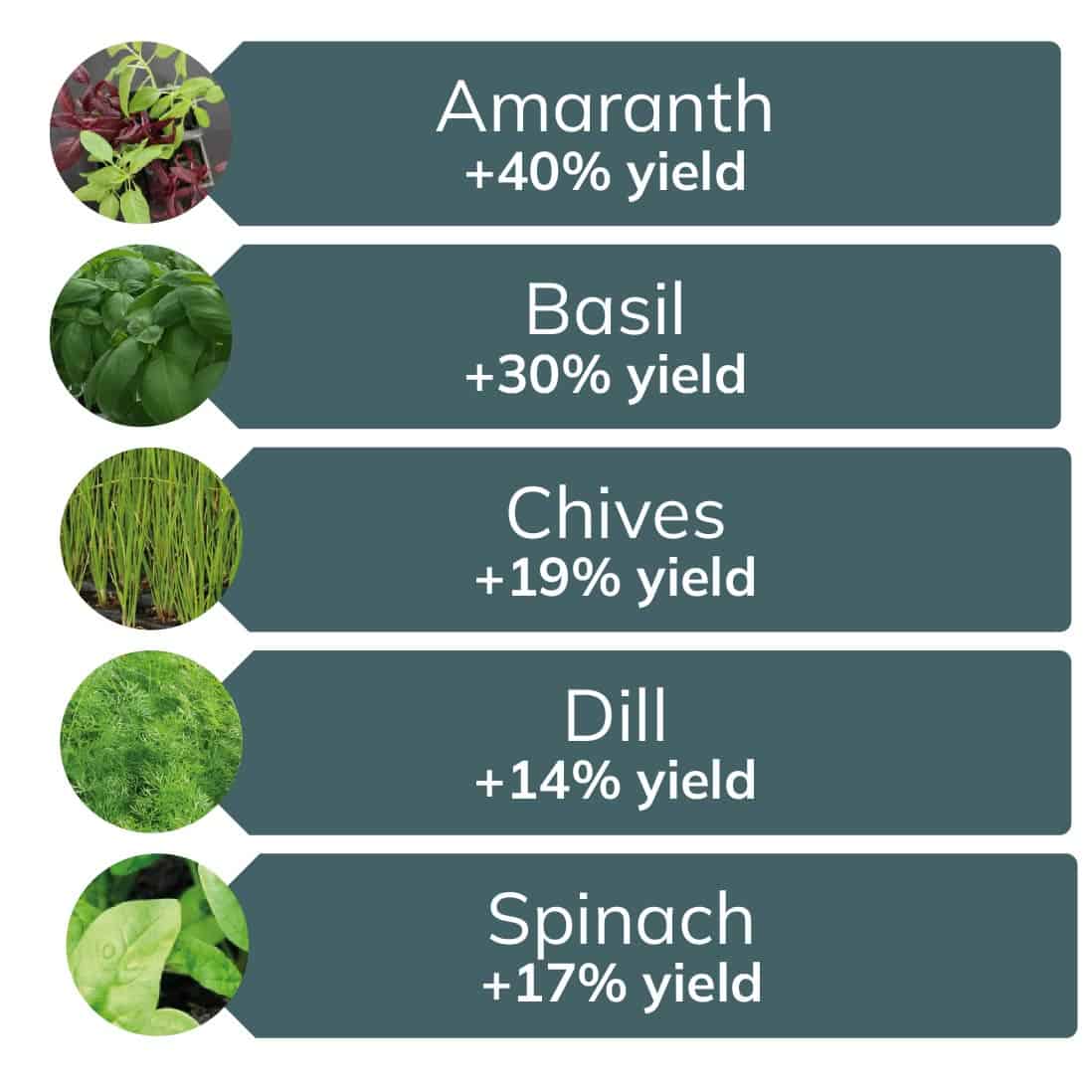

Customer assessments of our cold plasma seed treatment protocols have shown many benefits to plant health and crop performance with potential to increase yield by 15-25%.

Customer assessments of our cold plasma seed treatment protocols have shown many benefits to plant health and crop performance with potential to increase yield by 15-25%.

Applications for Zayndu's Seed Health Treatment Protocols

Vertical

Our seed health treatments vitalize seeds, delivering increased yield through improved health and increased germination.

Learn more

Greenhouse

In a controlled environment overall plant health is essential to help improve resilience against cross-contamination and increase productivity.

Learn more

Poly Tunnel

Improved seed health and germination rates can dramatically reduce the risk of crop losses.

Learn more

Micro herbs and bagged salad leaves production

Zayndu systems can be used to treat large volumes of seeds, multiple times a week. The process increases the rate and consistency of germination, boosting productivity and removing the need for additional chemicals and fertilisers.

Learn more

High value seed

Some seeds - such as basil - cannot be treated with water as they are 'mucilaginous' and clump together on contact with water, effectively eliminating any wet treatment process. The Zayndu system enables small batches of high value seeds to be processed for the first time without water or chemical residues.

Learn more

Natural Seed Producers

With the move to regenerative farming, the demand is set to increase for chemical-free treatments that improve the resilience and overall health of a seed used in more natural processes.

Learn more

High Risk Seeds

Some crops such as legumes, which includes peas and lupins, are particularly vulnerable to crop losses. Zayndu's technology has been shown to successfully improve the health and resilience of peas grown for pea shoots and is in field trials for lupin seed.

Learn moreInterested??

If you are interested in finding out how our cold plasma seed health treatment systems can help improve your productivity, crop yields and crop success rates, please get in touch with our team or subscribe to our newsletter.